The process of aluminium extrusion is truly captivating playing a role in contemporary manufacturing practices across various sectors. Whether its for marvels or vital automotive parts aluminium extrusion offers adaptability, efficiency and eco friendliness. This comprehensive examination delves into the nuances of aluminium extrusion shedding light on its core principles, uses, advantages and the environmental impact associated with its widespread adoption.

Unravelling the Fundamentals of Aluminium Extrusion

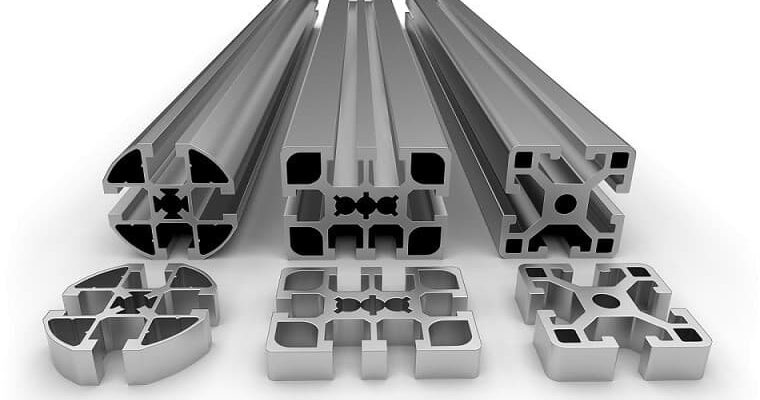

At its essence aluminium extrusion entails pushing aluminium alloy through a specifically shaped opening in a mould to produce elongated and uniform cross section profiles. The journey commences with heating aluminium billets—often crafted from materials—to a temperature that renders them pliable. Subsequently the softened aluminium is propelled through a mould via pressure to achieve the desired form.

Essential Tenets of Aluminium Extrusion

The beauty of aluminium extrusion lies in its capability to craft profiles with precise measurements. Custom designed dies constructed from steel are employed to fabricate distinct shapes—ranging from basic rods and tubes to elaborate designs for architectural embellishments or intricate automotive components. These extruded profiles can be further refined through techniques such, as cutting, bending and machining to cater to application needs.

Industries Utilizing Aluminium Extrusion

The use of aluminium is widespread across various industries;

- Architecture;Modern architectural designs rely on aluminium profiles for windows, doors, curtain walls and structural elements due to their lightweight nature and durability.

- Transportation;The automotive and aerospace fields utilize aluminium extrusions for body frames, engine parts and interior components to enhance fuel efficiency and performance.

- Electronics;Heat sinks, chassis and frames for devices benefit from the thermal conductivity and corrosion resistance offered by aluminium extrusions.

- Consumer Goods;The versatility of aluminium extrusion allows for the creation of appealing and functional products in industries ranging from furniture to household appliances.

Advantages of Aluminium Extrusion

- Lightweight;The low density of aluminium results in components that are both lightweight and strong making them well suited for applications where weight is a critical consideration.

- Corrosion Resistance;Aluminium naturally develops a protective oxide layer that boosts its durability and ability to resist corrosion in challenging environments.

- Design Flexibility;Custom profiles can be created with ease enabling designers to innovate and optimize product designs, for enhanced performance, aesthetics and functionality.

- Sustainability;Aluminium extrusion is highly sustainable as a significant portion of the material comes from recycled sources. Moreover its ability to be recycled ensures that it has an impact on the environment from start to finish.

Environmental Considerations

Despite the advantages of recycling and energy efficiency associated with aluminium extrusion there are challenges to be addressed. The extraction and processing of aluminium require energy leading to the emission of greenhouse gases. Furthermore the disposal of aluminium products at the end of their useful life presents recycling difficulties although steps are being taken to improve collection and recycling systems.

In Conclusion

Aluminium extrusion is an sustainable manufacturing method used across various industries. Its capacity to create profiles with accuracy and speed makes it an essential component in contemporary engineering and design. While it offers benefits such as lightweight construction, resistance to corrosion and flexibility in design it is crucial to address the environmental impacts and strive for sustainability, throughout the lifecycle of aluminium.

Explore the range of bespoke aluminium profiles and components at the top retailer, in this field.

By gaining insight into the principles and applications of aluminium extrusion manufacturers and designers can harness its potential to develop solutions that cater to the evolving needs of todays industries.

Comments